Plate rolling machine are essential in the metalworking industry, allowing manufacturers to bend and shape metal sheets into cylindrical or conical forms with high precision. Among the different types available, the 3 roll plate rolling machine is one of the most widely used due to its balance of efficiency, versatility, and reliability. To understand how these machines function, it is necessary to look closely at their key components and how each part contributes to overall performance.

Frame and Structure

The frame of a plate rolling machine acts as its backbone, providing strength, stability, and durability. Because the machine deals with heavy metal plates, the frame must be strong enough to handle stress without bending or vibrating. High-quality steel is typically used in manufacturing the frame to ensure the machine can perform consistently over years of operation. A weak frame would compromise accuracy and safety, making this one of the most important components.

Rolls (Upper and Lower)

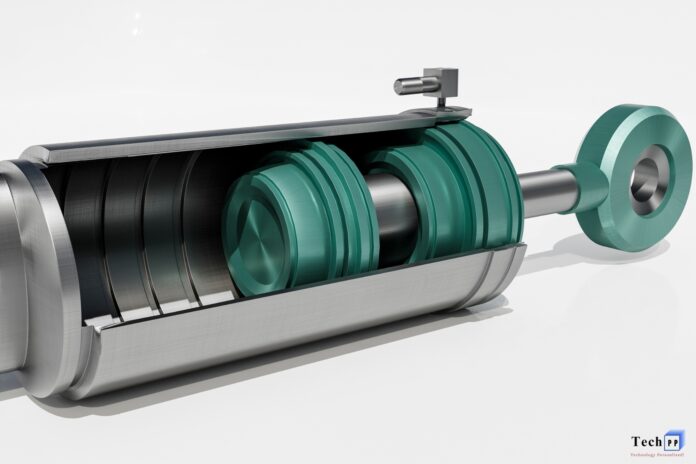

The rolls are at the heart of the machine and are directly responsible for bending the metal plate. The upper roll applies pressure to the sheet, forcing it into the desired shape, while the lower rolls provide support and feed the plate through the machine. These rolls are usually crafted from hardened steel to withstand the wear and tear of constant operation. The precision and smoothness of the rolling process largely depend on the quality and alignment of these rolls.

Drive System

The drive system supplies the power that rotates the rolls and moves the plate through the machine. It usually consists of electric or hydraulic motors, gears, and transmission systems. A strong drive system ensures smooth and consistent rolling even with thick plates. In modern machines, advanced drive systems allow precise speed control, improving accuracy and reducing the risk of mistakes during operation.

Hydraulic System

The hydraulic system provides the pressure necessary for bending metal plates. By controlling the force applied to the rolls, hydraulics make it possible to work with a variety of materials and thicknesses. Smooth operation and consistent pressure are critical for achieving uniform bends, and a well-designed hydraulic system ensures that every plate rolled matches the required specifications.

Control Panel

The control panel serves as the brain of the plate rolling machine. Operators use it to adjust critical parameters such as roll positioning, pressure levels, and rolling speed. In advanced CNC machines, the control panel offers programming features that automate operations and allow the machine to create highly precise shapes with minimal manual input. This reduces errors and increases efficiency in production.

Pinching Mechanism

The pinching mechanism holds the plate firmly between the rolls, preventing slippage during the rolling process. Without a strong pinching mechanism, the plate could shift, leading to uneven bends or wasted material. This component ensures that the plate remains stable throughout the operation, which is essential for accuracy and safety.

Side Supports and Central Supports

When working with large or heavy plates, there is always the risk of sagging during rolling. To solve this, plate rolling machines are equipped with side supports and central supports that keep the plate aligned and steady. These supports help maintain accuracy, especially when producing large-diameter cylinders or cones.

Cone Rolling Device

In cases where conical shapes are required, a cone rolling device is used. This attachment allows the operator to feed one side of the plate at an angle, creating the tapered shape. While not needed for every project, it is a valuable feature for industries that require specialized shapes, such as pressure vessels or certain construction applications.

Safety Systems

Heavy machinery requires strict safety measures. Plate rolling machines are fitted with safety systems such as emergency stop buttons, protective covers, and advanced sensors that monitor operations. These systems protect both the operator and the machine, preventing accidents and ensuring compliance with safety regulations.

Lubrication System

Because the rolls and gears are in constant motion, lubrication is essential to reduce friction and wear. A built-in lubrication system ensures that all moving parts are properly maintained, extending the life of the machine and ensuring smoother operations. Regular lubrication also minimizes the chances of unexpected breakdowns.

Applications of Plate Rolling Machines

Plate rolling machines are used across industries including shipbuilding, oil and gas, construction, and pressure vessel manufacturing. They are capable of producing pipes, tanks, and cylindrical or conical structures of various sizes. Their versatility and precision make them indispensable tools in large-scale manufacturing environments.

Importance of Quality Components

Every component of the machine, from the frame to the hydraulic system, directly impacts performance. A poorly built roll or weak drive system can compromise results, while advanced systems improve precision and productivity. Leading manufacturers like miharmle-cnc.com focus on engineering machines with superior materials and innovative technology to meet modern industrial needs. For companies, investing in machines with reliable components is essential for efficiency and long-term cost savings.

Tips for Operators

Operators should always perform regular inspections before use, keep rolls clean and lubricated, and choose the correct pressure based on plate thickness. It is equally important to follow safety protocols and undergo training, especially when using CNC control panels. Proper handling not only ensures accurate results but also extends the life of the machine

Conclusion

The key components of a plate rolling machine each play a vital role in its operation. From the sturdy frame and high-quality rolls to the hydraulic system and control panel, every part contributes to precision, safety, and efficiency. By understanding these elements, operators and manufacturers can maximize the machine’s performance. Plate rolling technology continues to evolve, offering industries powerful solutions for shaping metal with accuracy and reliability.