The burst test procedure is a critical quality control measure used in various industries, including packaging, textiles, paper, and corrugated materials. This test evaluates the strength and durability of materials by measuring their resistance to rupture under pressure. A bursting strength tester digital is an advanced device that ensures accurate and repeatable results, making it indispensable for manufacturers and testing laboratories.

In this article, we will explore the burst test procedure in detail, covering its importance, working principles, testing standards, and step-by-step execution using a digital bursting strength tester.

1. Importance of Burst Testing

Burst testing is essential for:

- Quality Assurance: Ensures materials meet industry standards and customer requirements.

- Product Safety: Prevents failures in packaging and textiles that could lead to damage or safety hazards.

- Regulatory Compliance: Adheres to international standards such as ISO, ASTM, and TAPPI.

- Performance Evaluation: Determines the durability of materials under stress.

Industries that rely on burst testing include:

- Packaging (corrugated boxes, flexible films)

- Textiles (fabrics, non-wovens)

- Paper and pulp (cardboard, paperboard)

- Medical (surgical gowns, sterile packaging)

A digital bursting strength tester enhances accuracy, reduces human error, and provides digital data recording for better analysis.

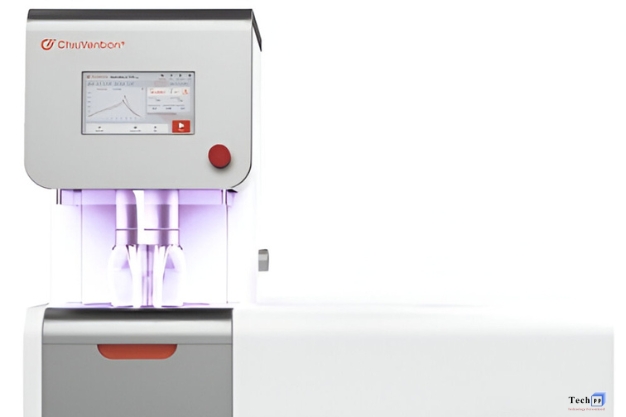

2. Working Principle of a Digital Bursting Strength Tester

A bursting strength tester digital operates by applying hydraulic or pneumatic pressure to a material sample until it bursts. The key components include:

- Test Head: Holds the sample in place.

- Diaphragm: Expands to apply uniform pressure.

- Hydraulic/Pneumatic System: Generates controlled pressure.

- Digital Display & Software: Records burst strength in kPa or psi.

The tester measures the maximum pressure (bursting strength) required to rupture the material, providing precise and repeatable results.

3. Burst Test Procedure Using a Digital Bursting Strength Tester

3.1 Preparation

Sample Selection:

- Cut samples to the required size (typically circular or square).

- Ensure samples are free from wrinkles, cuts, or defects.

Calibration:

- Calibrate the bursting strength tester digital according to manufacturer guidelines.

- Verify pressure sensors and zero-point adjustment.

Test Environment:

- Maintain standard temperature and humidity (e.g., 23°C ± 2°C and 50% ± 5% RH as per ISO 2758).

- 3.2 Test Execution

Mounting the Sample:

- Place the sample between the clamping rings of the tester.

- Ensure even tension without overstretching.

Applying Pressure:

- Start the test using the digital interface.

- The diaphragm expands, applying increasing pressure until the sample bursts.

Recording Results:

- The digital bursting strength tester automatically records the peak pressure (burst strength).

- Multiple tests are performed for statistical reliability.

3.3 Post-Test Analysis

- Calculate the average burst strength from multiple samples.

- Compare results against industry standards (e.g., ASTM D3786 for textiles, ISO 2758 for paper).

- Generate reports using the tester’s software for quality documentation.

4. Industry Standards for Burst Testing

Different industries follow specific standards:

| Standard | Application | Test Method |

| ISO 2758 | Paper & board | Hydraulic burst test |

| ASTM D3786 | Textiles (Mullen test) | Diaphragm bursting strength test |

| TAPPI T403 | Corrugated fiberboard | Bursting strength evaluation |

| ISO 13938-1 | Fabrics (pneumatic method) | Hydraulic burst test for textiles |

A digital bursting strength tester can be programmed to comply with these standards, ensuring consistency across tests.

5. Advantages of Using a Digital Bursting Strength Tester

- High Accuracy: Eliminates manual reading errors.

- Automated Calculations: Instantly computes average burst strength.

- Data Storage: Saves test results for traceability.

- User-Friendly Interface: Simplifies operation with touchscreen controls.

- Multi-Material Testing: Compatible with paper, textiles, and packaging.

Common Challenges & Troubleshooting

- Sample Slippage: Ensure proper clamping force.

- Inconsistent Results: Check calibration and environmental conditions.

- Diaphragm Wear: Replace diaphragms periodically for accurate pressure application.

ALSO READ : CÑIMS and the Rise of Smart Enterprises

Conclusion

The burst test procedure is a vital assessment for material strength, and a digital bursting strength tester enhances its precision and efficiency. By following standardized testing protocols, industries can ensure product reliability, regulatory compliance, and customer satisfaction.

Investing in a high-quality bursting strength tester digital streamlines quality control, reduces waste, and improves manufacturing processes. Whether for packaging, textiles, or paper products, accurate burst testing is key to delivering durable and high-performance materials.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk