Stainless steel is a sturdy and popular material. It is used in many industries, from kitchen gear to commercial leaders. The most common types of chrome steel are 304 and 316. Choosing the proper type is vital for the task. In this manual, we are able to give an explanation for the distinction in very simple words.

What is Stainless Steel?

Stainless steel is a form of metal that doesn’t rust easily. It remains vivid and robust even after a few years. Stainless steel is made by mixing iron with metals such as chromium and nickel. Chromium facilitates the metal to face up to the rust, and nickel makes it sturdy and extra durable.

This steel is used in lots of areas of life. It is in homes, machines, kitchens, and the food system. Stainless steel is also used in automobiles, clinical systems, and commercial machines. It is famous because it is sturdy, lasting longer and appears easy and vibrant.

304 Stainless Steel

304 stainless steel is the most common kind. It has desirable power and is easy to work collectively. It can oppose the struggle in many situations.

304 Important Stainless Steel Features:

- Good corrosion resistance within the popular environment

- Strong and sturdy

- Easy to make, cut, and lengthen

- Cheaper

Kitchen gear, system, and pipes are used

304 stainless steel is widely used in stainless steel CNC machining. This means it can be cut and shaped with machines to make custom parts. And it is also suitable for projects where the part will not be exposed to powerful chemicals or salty water.

316 Stainless Steel

316 stainless steel is much like 304, however, it has an extra element: molybdenum. This makes it more resistant to rust, mainly with salt and chemical compounds.

316 Important Stainless Steel Features:

- Better corrosion resistance than 304

- Strong and durable

- Works nicely in an inflexible environment with the marine or chemical industries.

- A little extra highly-priced

- Medical equipment, chemical equipment, and marine parts are used

316 stainless steel is also used in stainless steel for injection molding. This is because it can handle harsh chemicals and high temperatures, which helps make better molds and parts.

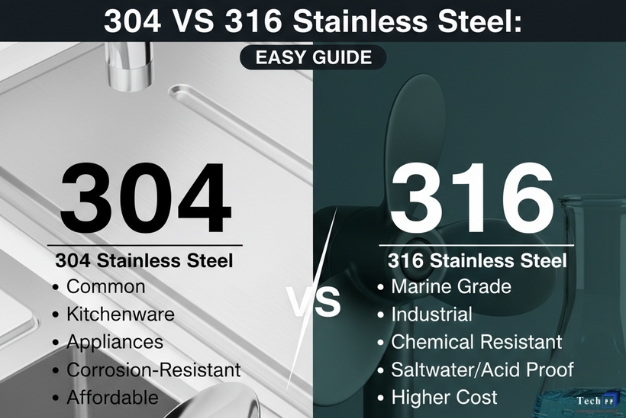

Differences Between 304 and 316 Stainless Steel

304 vs 316 Stainless Steel

- 304: 18% Chromium, 8% Nickel. Cheap, general use, kitchen & industry.

- 316: 16% Chromium, 10% Nickel, +2% Molybdenum. Expensive, stronger, best for saltwater & chemicals.

Corrosion resistance

316 is better than 304 to withstand rust in salt water and chemical compounds. If you operate chrome steel in a sea or chemical environment, 316 is a safe alternative.

Cost

304 is cheap and works properly in ordinary situations. 316 more value, but long items in stiff surroundings. The variety between them depends on the utility and the price range.

Feasibility

Both 304 and 316 are proper for machining and shaping. 304 is a little easier to reduce and bend. Three hundred sixteen might also require greater care throughout CNC machining, however modern-day machines cope with it well.

Applications of 304 Stainless Steel

304 stainless steel may be very flexible. Some general uses of:

- Kitchen sink and utensils

- Food processing system

- Pipes and appropriate

- Decorative panel

- Generally machine component

The food is simple and easy, strong and secure to touch.

Applications of 316 Stainless Steel

316 stainless steel is used when greater corrosion resistance is needed. Some examples:

- Sea equipment and boat components

- Medical device

- Chemical system equipment

- External structures near the sea

316 is chosen for components that can withstand rigid chemical substances, salt water, or severe situations.

Choosing Between 304 and 316

When choosing stainless steel, you could ask these questions:

- Will the component be exposed to salt or chemical substances? Use → 316

- Are expenses extra critical? → 304 less expensive and nonetheless sturdy

- Will it require CNC machining or forming? → Both work, but 304 is a piece easy

How long will the element remain? → 316 goods longer beneath hard situations

Tips for Working with Stainless Steel

- Use a speedy domestic gadget: A fast home system without difficulty, and avoid scratches.

- Keep the surfaces clean: Wipe the dirt to prevent rust.

- Use the coolant: Metals and the system are blanketed while slicing the coolant.

- Store in dry locations: Keep stainless steel dry to prevent rust.

These steps help stainless steel to become final, robust, smooth, and long.

Conclusion

Both 304 and 316 chrome steel are strong, durable and useful. 304 is ideal for normal use and modern environment. 316 is better for tough conditions and long -lasting additives.

Understanding the difference helps you pick out the right clothes. Whether you want chrome steel CNC machining or stainless steel for injection casting, deciding on the proper type of strength will result in longer and higher.

Consider using the environment, charges, and components before choosing between 304 and 316 stainless steel. By selecting the right type, you could save money, reduce protection, and get higher outcomes.